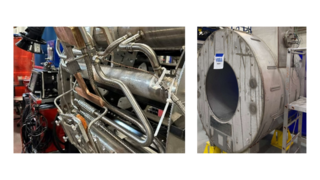

Case Study: Philips partners with Nelson Global to achieve zero-defect tubing for advanced MRI systems

Challenge:

Philips, a global leader in medical imaging, required extremely precise stainless-steel tubes for its MRI machines. Because MRI systems demand absolute reliability and zero contamination, our team had to solve three major challenges simultaneously:

- Internal Cleanliness: Tubes had to be completely clean inside, yet no chemical cleaning agents could be used.

- External Perfection: Any clamping marks or scratches had to be less than 5% of the tube’s wall thickness – just 0.889 mm.

- Extreme Precision: Tube ends needed to maintain less than 0.1 mm perpendicularity.

Solution:

To meet Philips’ zero-defect expectations, Nelson Global’s team in Chian focused not only on correcting issues but also on building long-term systems that would eliminate them at the source. Internal residue was traced back to raw materials, prompting a redesigned “source control” cleaning approach that prevented contamination from the very beginning of the manufacturing process.

For the exterior surface requirements, traditional measurement tools were too limited to quantify such small imperfections. The team addressed this by introducing nylon tooling that eliminated common causes of dents and marks, and by developing a customer-approved “Golden Sample” alongside a simple but consistent visual inspection method known as the fingernail test, which ensured operators could quickly determine whether a surface met expectations without relying on judgment.

The entire production flow was then consolidated into a dedicated area for Philips medical products. By performing all steps – from raw materials to finished parts – within one controlled space, the team dramatically reduced the change of damage that can occur when components move through multiple handling stages. Engineering, production, and operations worked closely throughout the project to upgrade equipment, refine standards, and align the layout and resources needed to achieve repeatable quality.

Results:

The enhanced processes delivered measurable improvements that aligned with the stringent performance and reliability expectations of medical imaging systems:

- Consistent internal cleanliness, achieved by fully eliminating the residue traced to incoming materials.

- Exceptional surface quality, with external marks reduced to levels that met the customer’s strict cosmetic standards.

- Precision dimensional control, including tube-end perpendicularity within the required 0.1 mm.

- A stable, repeatable manufacturing process supported by improved inspection standards and a controlled production environment.

Impact:

This project demonstrates Nelson Global’s ability to apply disciplined engineering, process innovation, and cross-functional expertise to solve complex manufacturing challenges, regardless of industry. By transforming stringent, highly specific requirements into scalable, controlled processes, our team delivered components that meet the quality, cleanliness, and precision standards essential for advanced, safety-critical applications. It reinforces our role as a trusted partner for companies that rely on dependable, high-performance components in demanding environments.