Case Study: Nelson Global delivers low-temperature, high-durability bellows solution for next-generation harvesters

Challenge:

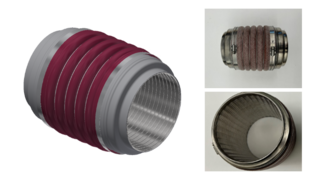

A key customer in the agricultural equipment sector required bellows for their harvesters that maintained a low skin temperature on exhaust components to improve operator safety. The challenge was to match the thermal, flexibility, and durability characteristics of a competitor’s stainless steel bellows while meeting the customer’s strict 250°C maximum skin temperature requirement.

Solution:

Nelson Global engineers approached the project with a focus on innovation and collaboration. Departing from traditional stainless steel designs, the team explored non-metallic composite materials paired with advanced insulation solutions. Multiple bellows design iterations were tested to optimize performance across all critical parameters: thermal management, flexibility, and durability.

Cross-functional collaboration was critical to the project’s success. Engineering, operations, and supply chain teams worked together to source materials, assemble prototypes, conduct rigorous testing, and communicate progress with the customer. This integrated approach allowed the team to refine designs efficiency and effectively.

Results:

The project resulted in a bellows solution that achieved the required low skin temperature while maintaining the flexibility and durability performance expected by the customer. Additionally, the innovative design delivered cost savings without compromising on quality or safety.

Impact:

This project underscores Nelson Global’s commitment to proactively seeking opportunities to enhance products through innovation. By combining new materials, design iterations, and cross-functional teamwork, the engineering team delivered a solution that improved safety, maintained performance, and added value for the customer.